Hydraulic wire saw machine is a powerful cutting tool that uses a diamond-coated wire to slice through hard materials like reinforced concrete, stone, metal, and even underwater structures. Unlike traditional saws or drills, this machine operates with minimal noise, vibration, and dust, making it ideal for projects where precision and safety are top priorities. WhatsApp/WeChat/Phone/Skype+86 138 3715 9132

Hydraulic Wire Saw Machine Parameters

| Rope drive hydraulic | Hydraulic power station parameters: | ||

| Motor type | HM80 (double cylinder) | Rated output power: 22/25KW | 22/25KW |

| Input power | 25/33HP | Working voltage 380V50HZ | 380V50HZ |

| Shaft output speed | 350/940/1300r/min | Hydraulic pump station type | gear pump |

| Maximum rope length | 20 meters | Main drive motor working flow | 40-100L/min |

| Feeding method | Fully automatic hydraulic | Working pressure | 15-20Mpa |

| Cutting machine unit weight | 64KG | Fuel tank volume | 17L |

| Host drive motor weight | 14KG | Weight | 160kg |

| Total weight | 78KG | Size | 700*700*1200mm |

| Size | 1700*700*800mm | ||

Wire Saw Machine Applications

Building Renovation & Demolition

Cutting Thick Structures: Easily slice through heavy concrete walls, pillars, or beams when remodeling buildings, even in tight spaces where big machines can’t fit.

Removing Parts Safely: Take out sections of floors or ceilings without harming the rest of the structure, keeping nearby rooms or walls intact.

Bridge & Tunnel Projects

Precision Repairs: Create neat openings in bridges to fix damaged areas or add new sections, ensuring the structure stays strong.

Underwater Work: Cut through tough tunnel walls, dam supports, or piers even when submerged in water, where regular tools struggle.

Industrial & Construction Tasks

Metal Cutting: Slice through thick metal pipes, machinery parts, or heavy-duty equipment bases smoothly, like cutting through butter.

Stone Shaping: Carve granite or marble blocks into perfect shapes for countertops, sculptures, or building materials without cracking or wasting stone.

Emergency Rescue Operations

Disaster Cleanup: Quickly clear collapsed concrete slabs, twisted metal, or debris after earthquakes or building collapses, helping rescue teams reach trapped people faster.

Safe Cutting: Handle dangerous situations like cutting through unstable wreckage or sharp rubble without creating sparks or causing further damage.

Hydraulic Diamond Wire Saws Working principle

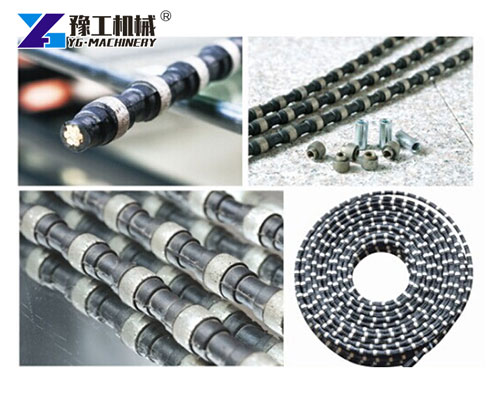

Hydraulic diamond wire saws are tough tools for cutting through almost anything. Imagine a super-strong “wire” with tiny diamond bits that grinds through materials like a hot knife through butter, without shaking or harming what’s around it. Here’s how they’re built:

1. The Power Source

Think of this as the tool’s heart. It pumps energy to keep the wire moving, like a car engine powers its wheels.

2. The Cutting System

A flexible wire coated with diamond bits (like sandpaper, but stronger)

Wheels that guide the wire in a loop

A motor that spins the wire fast, letting it slice smoothly

The diamond bits slowly wear down the material as the wire moves, creating clean cuts that can go straight, curve, or even tackle tricky angles. It’s like drawing with a pencil that never breaks, no matter how thick the paper!

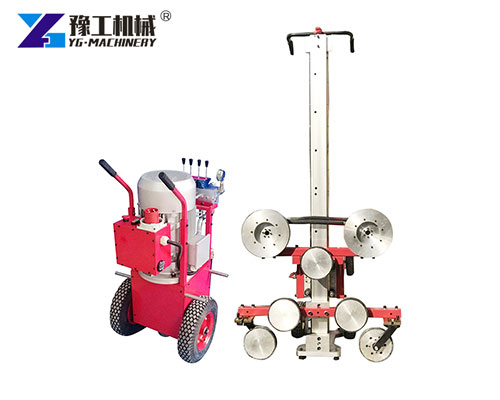

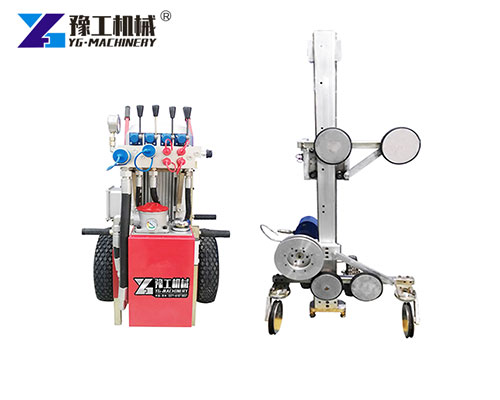

Hydraulic Wire Saw Composition

Understanding the parts of a hydraulic wire saw helps you use it effectively:

Hydraulic Power Unit:

Provides the energy to drive the wire.

Typically includes a motor, hydraulic pump, and controls.

Wire Saw Unit:

Diamond Wire: A loop of steel wire embedded with diamond beads.

Pulleys and Wheels: Guide the wire and maintain tension.

Hydraulic Motor: Powers the wire’s movement.

Accessories:

Cooling systems (to prevent overheating).

Anchoring tools for stability during cutting.

5 Features of Hydraulic Wire Saw Machine

Speed That Surprises

Slice through materials faster than traditional tools—imagine cutting through a whole garage wall in the time it takes to brew coffee. Perfect for tight deadlines.

Light as a Backpack

Carry it like a camping tent, set it up quicker than assembling furniture. No heavy machinery headaches—works anywhere from rooftops to muddy construction sites.

Built Like a Tank

Rain, dust, or freezing temperatures? No problem. These saws keep working through conditions that would send other tools to the repair shop.

Anyone Can Master It

If you can use a smartphone, you can operate this. Intuitive controls mean new workers can start cutting confidently in under an hour.

Forget Frequent Fixes

With a design simpler than a bicycle, there’s almost nothing to break. Spend less time tinkering and more time cutting—year after year.

How to Choose the Right Wire Saw Machine

Ask yourself these questions:

What material are you cutting?

Concrete, metal, or stone? Each requires a specific diamond wire type.

What’s your budget?

Hydraulic models are pricier but more powerful. Electric saws are cheaper for light use.

Where are you working?

Tight spaces? Underwater? Hydraulic saws excel here.

How fast do you need to finish?

For large projects, prioritize speed and power.

Method Steps of Wire Saw Cutting

Method Steps of Wire Saw Cutting

Set Up:

Anchor the machine securely.Loop the diamond wire around the material.

Start Cutting:

Turn on the hydraulic power unit.Let the wire grind through the material at a steady pace.

Cooling:

Use water to cool the wire and reduce dust.

Finish:

Once the cut is complete, turn off the machine and inspect the result.

YG Wire Saw Manufacturer

YG Machinery manufactures hydraulic wire saws trusted by builders around the world, from the US to Australia to Singapore, offering affordable hydraulic wire saws that combine power, precision and safety. Our machines cut through concrete, metal and stone with ease, perfect for bridges, countertops or underwater repairs. With reliable after-sales support, we simplify tough jobs while saving time and money. Choose YG Wire Saws for smarter demolition. Get a free quote now! WhatsApp/WeChat/Phone/Skype+86 138 3715 9132