YG Machinery successfully sold two Wire Saw Machines to Singapore.

Singapore, with its booming construction and infrastructure development, has a great need for advanced cutting equipment. The Wire Saw Machines from YG Machinery are expected to play an important role in various projects there.

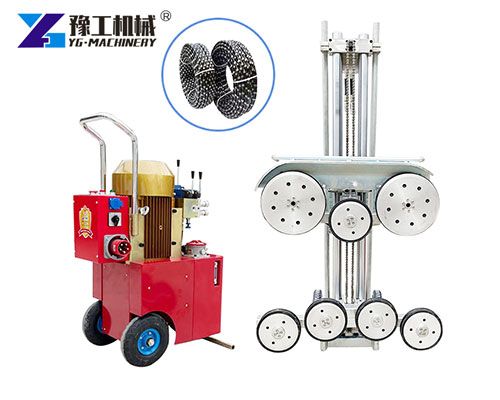

Parameter of Hydraulic Wire Saw Machine for Sale

| Wire Saw Wheel Parameters | Hydraulic Pump Parameters | ||

| Wire Drive Mode | hydraulic | Motor Power | 22/25kw |

| Motor Type | HM-80, 2 Cylinders | Voltage | 220V/380V, 50Hz |

| Minimum Input Power | 25HP/33HP | Hydraulic Pump Type | Gear Pump |

| Output Shaft Speed | 350/940/1300r/min | Main Drive Motor | 40-100L/min |

| Maximum Wire Length | 20m | Working Pressure | 15-20Mpa |

| Feeding Method | Fully hydraulic | Oil Tank Capacity | 17L |

| Wire Saw Wheel Weight | 64kg | Weight | 160kg |

| Motor Weight | 14kg | Size | 700*700*1200mm |

| Size | 1700*700*800mm |

Application of Wire Saw Machine

Wire saw machines, especially those using diamond – tipped wires, are highly adaptable tools used in various industries.

Building Demolition & Renovation

In construction sites, wire saws are essential for safely dismantling old buildings. They can precisely cut through thick concrete walls, floors, and even steel – reinforced structures.

For example, when removing part of a building during renovations, these machines make clean, controlled cuts, reducing noise, dust, and the need for heavy, messy equipment like jackhammers.

This saves time and labor while minimizing disruption to surrounding areas.

Stone Mining & Processing

In quarries, diamond wire saws are used to extract large blocks of natural stone like granite, marble, and limestone.

The sharp, durable diamond – coated wires slice through hard rock with high accuracy, creating smooth surfaces and reducing waste.

This precision is critical for producing high – quality stone slabs used in buildings, monuments, and decorative projects.

Bridge & Tunnel Construction

During the building of bridges, tunnels, or highways, wire saws play a key role in shaping concrete components.

They cut precast concrete pieces (like pillars or tunnel segments) to exact sizes and angles, ensuring parts fit together perfectly for structural safety.

This precision is vital for maintaining the stability of large infrastructure projects.

Metal Fabrication & Manufacturing

Wire saws are widely used in metalworking to cut through thick steel, aluminum, or other metal sheets and bars.

Whether in factories producing machinery, vehicles, or industrial parts, these machines create clean, straight cuts without damaging the material.

They’re ideal for shaping metal components used in engines, frames, or heavy equipment, where precision is key.

Renewable Energy Projects

In the green energy sector, wire saws help manufacture components for solar panels and wind turbines.

For solar panels, they cut thin, delicate silicon wafers (the core of solar cells) with extreme precision.

In wind energy, they shape large steel or composite parts for turbine bases and blades, ensuring these components meet strict safety and performance standards.

Waste & Material Recovery

Wire saws are useful for recycling concrete, asphalt, or metal waste. When breaking down old roads, buildings, or industrial materials, they cut large chunks into manageable pieces for reuse.

For example, they can separate steel rebar from crushed concrete, making it easier to recycle both materials. This supports sustainable practices by reducing landfill waste and conserving resources.

Concrete Wire Saw Machine Usage Precautions

YG Machinery sells concrete wire saws.

When using a wire saw machine, please take the following precautions:

Operator Training: Only trained operators should use the diamond wire saw cutting machine. They should be familiar with the operation manual and safety regulations of the machine.

Regular maintenance: This includes checking the wire saw, lubricating the moving parts, and inspecting the electrical system. Regular maintenance can make the machine last longer and ensure that it operates safely.

Safety Protection: Operators should wear safety glasses, gloves, and a helmet. They should also make sure that the working area has good ventilation and is free of anything that could get in the way.

YG Machinery: Your Trusted Wire Saw Partner

With years of expertise in cutting equipment, YG Machinery is a leading wire saw manufacturer delivering high – quality, adaptable solutions for global industries.

Equipped with high – torque motors and precision controls, our diamond wire saws ensure efficient, accurate cutting—even for tough materials like concrete or stone.

Benefits: minimal downtime, lower energy use, and reliability for heavy projects.

No two needs are alike. We tailor machine size, power, and cutting capacity to your workflow—whether for small renovations or large industrial tasks.

Share your requirements, and our engineers design a solution to boost productivity and ROI.