Mini excavator attachments for sale transform compact machines into versatile tools for diverse scenarios. These professional-grade tools not only enable basic excavation but also tackle over 20 complex tasks like crushing, cutting, pulverizing, and compacting with quick tool changes.

The innovative thumb attachment, featuring a mechanical linkage design, offers precise 360° gripping capabilities, excelling in scenarios such as construction debris sorting and pipeline laying.

Meanwhile, the heavy-duty ripper, equipped with high-strength alloy steel teeth, effortlessly breaks through frozen soil and concrete layers, significantly boosting efficiency with its hydraulic-driven system.

For confined-space operations, telescopic-arm mini excavators can maneuver freely in narrow alleyways, paired with high-frequency breakers to execute precision demolitions unreachable by conventional equipment. In indoor settings, electric-powered silent attachments reduce noise to minimal levels while incorporating dust collection systems, adhering to green construction standards.

This highly integrated solution establishes mini excavators as all-in-one assistants for municipal maintenance, landscaping, and industrial repairs, truly realizing the revolution of multi-functional construction. WhatsApp/WeChat/Phone/Skype +86 138 3715 9132

Mini Excavator Attachment for Sale Categories

Shattered/Removed Engineering Equipment

| Equipment | Applications | Features |

| 1. Hydraulic Breaker | – Breaking rocks and demolishing concrete (e.g., old building renovations) – Mining operations and foundation construction | – High-frequency impact force for crushing hard materials – Compatible with various excavator models – Built-in hydraulic valve for stability – Triangular/tower shapes for versatility |

| 2. Hydraulic Pulverizer | – Demolishing buildings (e.g., crushing reinforced concrete blocks) – Metal processing at recycling stations | – Movable and fixed jaws for high efficiency – Hydraulic-driven with adjustable power – Single-person operation – Wear-resistant steel for durability |

| 3. Muti Shear (High-Altitude) | – High-rise building demolition (e.g., cutting steel beams) – Dismantling bridges or large structures | – Wide-opening design for thick bars – Stable in high-altitude work – Synchronized mechanism for precision – 360-degree rotation flexibility |

| 4. Single Cylinder Shear | – Cutting medium-thickness metal (e.g., iron plates) – Dismantling small scrap vehicles | – Simple single-cylinder maintenance – High-toughness blades for clean cuts – Lightweight for small excavators – Quick blade replacement |

| 5. Double Cylinder Shear | – Cutting heavy steel (e.g., H-beams, rails) – Demolishing large concrete structures | – Dual-cylinder doubles cutting force – Ultra-wear-resistant blades – Hydraulic rotation for angles – Heavy-duty impact-resistant frame |

| 6. Hydraulic Power Shear | – Extreme environments (e.g., disaster rescue) – Ultra-hard materials (e.g., concrete piles) | – Top-tier hydraulic cutting power – Fully sealed for harsh conditions – One-button smart control – Modular low-maintenance design |

Intelligent Loading And Unloading Equipment

| Product | Applications | Product Features |

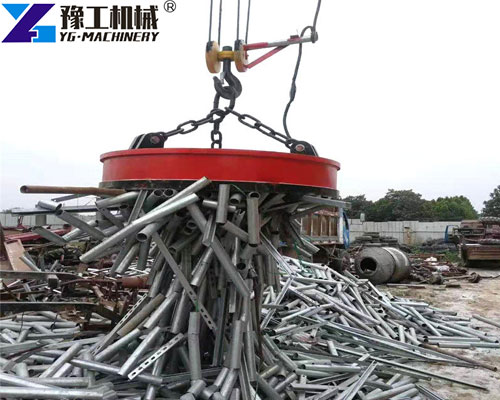

| Steel/Rock/Log Grabber | – Handling scrap metal, rocks, or logs (e.g., recycling yards, demolition sites) | – Multi-claw design for various materials. – Rotates 360° for flexible positioning. – Durable for heavy-duty use. |

| Orange Peel Grapple | – Grabbing debris or bulk materials (e.g., construction waste, loose metal) | – Petal-shaped claws for wide grip. – Strong grip in tight spaces. – Easy open/close control. |

| Clamp Bucket | – Securing loose materials like sand or gravel during transport. | – Adds grip to standard buckets. – Quick attachment for efficiency. – Reduces spillage. |

| Tilt Bucket | – Pouring materials at angles (e.g., landscaping, trench work). | – Adjustable tilt for precise dumping. – Minimizes material sticking. – Simple one-lever control. |

| Clamshell Bucket | – Digging or scooping loose soil, grains, or debris. | – Two-part shell for deep scooping. – Tight seal to prevent leaks. – Ideal for precision ta |

Compaction Piling And Auxiliary Equipment

| Product | Applications | Product Features |

| Hydraulic Plate Compactor | – Compacting soil or gravel (e.g., road construction, landscaping). | – High-frequency vibration for tight compaction. – Compact design fits narrow spaces. – Easy to operate with hydraulic controls. – Reduces manual labor. |

| Pile Hammer | – Driving piles into the ground (e.g., building foundations, bridges). | – Powerful impact force for deep penetration. – Adjustable strike energy. – Durable for long-term use. – Works with various pile types. |

| Ripper | – Loosening hard soil or rocky terrain (e.g., farming, excavation). | – Sharp tines break up compacted ground. – Adjustable depth control. – Reinforced steel construction. – Simple attachment to excavators. |

| Excavator Rake | – Clearing debris or leveling soil (e.g., post-construction cleanup). | – Flexible tines sort rocks and roots. – Lightweight for precise grading. – Quick hydraulic adjustment. – Reduces hand raking effort. |

| Hydraulic Power Thumb | – Gripping logs, rocks, or scrap (e.g., forestry, demolition). | – Acts like a “thumb” for better grip. – Bolt-on design for easy installation. – Adjustable pressure for delicate tasks. – Works with buckets or grapples. |

| Hydraulic Quick Hitch | – Switching tools rapidly (e.g., changing buckets, hammers). | – One-click tool attachment/detachment. – Safety locks prevent accidental drops. – Compatible with most excavator models. – Saves time and lab |

Mini Excavator Application Scenarios

| Scenario | Attachments | Technical Advantages |

| Narrow Space Maintenance | Grapple + Shear | Compact design for confined spaces, IP67 waterproof rating enhances durability, 200bar hydraulic power ensures efficient cutting |

| Paddy Field Drainage | Ditch Cleaner + Auger | CE-certified attachments enable combined operations, optimized for agricultural environments |

| Indoor Renovation | Compactor + Multi-Claw | Electric drive eliminates exhaust emissions, leak-proof claws prevent debris spillage |

| Orchard Management | Ripper + Tilting Bucket | 1.5-ton specifications deliver ideal power-to-weight ratio, quick coupler simplifies attachment changes |

How to Choose Mini Excavator Attachments

Define Project Requirements

Worksite Analysis

Space Constraints: For basements or alleys, select models under 80cm width (mini excavator for narrow spaces) with foldable attachments.

Environmental Compliance: Prioritize electric models (electric mini digger for indoor renovation) for noise levels <68dB and zero emissions.

Harsh Conditions: Opt for IP67 waterproof-rated attachments (IP67 waterproof electric mini excavator) for paddy fields or swamps.

Cost-Benefit Evaluation

Short-Term Projects: Rent low-frequency-use attachments like augers (auger attachment for mini excavator tree planting).

Long-Term Needs: Invest in CE-certified attachments (CE certified mini excavator attachments) for 3-5 years of extended service life.

Attachment Combinations: Maximizing Efficiency

Basic Earthwork Kit

Combo: Bucket (excavation) + Vibratory Compactor (compaction) + Tilting Bucket (slope shaping).

Applications: Yard renovation, utility trenching (best mini excavator for home use).

Key Specs: Ensure 200bar hydraulic systems (200bar hydraulic system mini excavator) for compaction power.

Agricultural Efficiency Kit

Combo: Ditch Cleaner (drainage) + Auger (auger attachment) + Multi-Claw Grapple (debris handling).

Applications: Rice field drainage (agricultural mini excavator for rice field drainage), orchard maintenance.

Key Specs: 1.5-ton models (1.5-ton mini excavator specifications) balance power and maneuverability.

Industrial Demolition Kit

Combo: Hydraulic Shear (metal cutting) + Rotating Grapple (rotating grapple for mini excavator) + Breaker.

Applications: Steel structure dismantling, scrap processing.

Key Specs: 360°rotating attachments enhance flexibility in tight spaces.

Mini Excavator Attachments for Sale Technical Parameter

| Parameter | Selection Advice | Pitfall Avoidance |

| Hydraulic Pressure | ≥200bar for breaking/shearing tasks | <180bar risks insufficient power |

| Quick Coupler Type | ISO 13031-compliant for compatibility | Non-standard couplers increase downtime |

| Attachment Weight | ≤80% of machine’s rated capacity | Overloading accelerates arm wear |

| Protection Rating | IP65+ for agriculture; IP67 for electric | Low waterproofing raises failure rates |

Scenario-Based Purchasing Examples

Case 1: Residential Yard Renovation

Pain Points: Limited space, minimal turf damage.

Recommended Setup:

Machine: 1.2-ton electric model (why electric mini excavators are better for environment).

Attachments: Rubber tracks (anti-slip) + Narrow bucket (0.15m³) + Compactor.

Cost Tip: Rent an auger for tree planting.

Case 2: Farm Drainage Project

Pain Points: Rapid monsoon-season channel clearing.

Recommended Setup:

Machine: 1.5-ton diesel model (agricultural mini excavator).

Attachments: Slope-sensing ditch cleaner + 4m extended arm.

Efficiency: CE-certified attachments achieve 10x manual labor output.

Maintenance & Value-Added Services

Mini Excavator Maintenance Tips

Inspect hydraulic oil filters every 50 hours to prevent sluggish performance.

Use ISO VG32 low-viscosity oil for winter startups (-20°C).

Upgrade Options

Choose suppliers offering retrofits (e.g., GPS tracking modules).

Opt for 3-year warranties covering hydraulic lines and seals.

By aligning attachments with project demands, users unlock multi-functional capabilities for their mini excavators.

Why Choose YG Machinery for Mini Excavator Attachments?

YG Machinery delivers high-performance mini excavator attachments through global certifications (CE/ISO) and innovative technologies. Its modular design covers full-scenario applications from narrow alleys (mini excavator for narrow spaces) to paddy field drainage (agricultural mini excavator for rice field drainage), quick couplers ensuring rapid tool switching.

Choosing YG guarantees triple advantages: cutting-edge technology , scenario adaptability , and sustainable value. Redefine small-scale equipment efficiency with YG’s innovation-driven solutions.

【WhatsApp/WeChat/Phone/Skype】+86 138 3715 9132