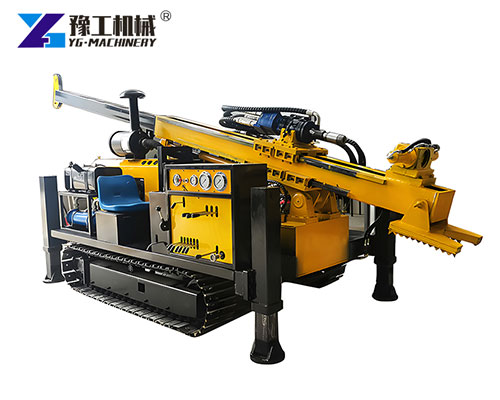

The fully hydraulic core drill is an advanced device designed for extracting core samples from the ground. It has revolutionized the drilling industry with its advanced technology and high performance. These rigs are widely used in geological exploration, mining, and construction engineering. Contact us via WhatsApp/WeChat at +86 138 3715 9132

Full Hydraulic Core Drilling Rig Parameter

| Model | YGX-400 | YGX-600 | YGX-800 | YGX-1000 |

| Drilling Depth(M) | 180-400-500 | 200-600-650 | 400-800-1000 | 500-1000-1100 |

| Rated pressure(MPA) | 21 | 21 | 25 | 28 |

| Rated Flow(L/min) | 168 | 192 | 260 | 300 |

| Heat Dissipation Mode | Air cooling+water cooling | |||

| Engine Brand | Yuchai | Yuchai | Yuchai | Cummins |

| Rated power/speed | 78kW/ 2400r/min | 92kW/ 2400r/min | 92kW/ 2400r/min | 154kW/2400r/min |

| Drilling Angle(°) | 0-90 | 45-90 | 45-90 | 45-90 |

| Lifting Force(T) | 12 | 16 | 24 | 30 |

| Feed Force(T) | 6 | 8 | 12 | 15 |

| Hydraulic Mud pump flow | 30-90(L/min) | 30-90(L/min) | 90-180(L/min) | 90-180(L/min) |

| Hydraulic Mud pump power | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) |

| Dimension | 4000*1900*1800mm | 4000*2000*1800mm | 5500*2100*2000mm | 6000*2200*2400mm |

| Weight | 4.3T | 4.5/5.5T | 6.5T | 7.5T |

Mechanical Principle of Hydraulic Core Drilling Rig for Sale

The mechanical principle of a Hydraulic Core Drilling Rig is based on the use of hydraulic power.

The hydraulic fluid transfers energy and controls the movement of the rig’s components. The hydraulic system consists of pumps, valves, and cylinders.

The pump pressurizes the hydraulic fluid, which then flows through the valves to the cylinders.

The cylinders convert the hydraulic energy into mechanical energy, driving the drill bit and other components of the rig.

Hydraulic Coring Drilling Rigs: Basic Components

A Full Hydraulic Coring Drilling Rig typically consists of the following basic components:

- Drill Bit

At the forefront of operations, the drill bit cuts into the ground to extract core samples. Depending on geological conditions, specialized bits are selected for optimal performance in rock, soil, or mixed formations. - Drill Rod

Building on this, the drill rod acts as a critical link, transferring rotational and axial forces from the rig to the bit. Its robust design ensures stability and precision during deep or angled drilling. - Hydraulic System

Integrating seamlessly with the mechanical components, this system powers the rig via pumps, valves, and cylinders. Regulating pressure and flow, it enables precise control over drilling speed and torque. - Rotary Table

Working in tandem with the hydraulic system, the rotary table generates rotational motion to spin the rod and bit. This synchronized action ensures consistent drilling efficiency across varying subsurface conditions. - Hoisting System

To complete the system, the hoisting mechanism raises and lowers the rod and bit into the borehole. Equipped with automated controls, it minimizes manual intervention while enhancing operational safety.

Applications of Hydraulic Core Drill Rigs

Full Hydraulic Core Drilling Rigs have a wide range of applications:

Geological Exploration: They are used to collect core samples from the ground to study the geological structure, identify mineral deposits, and assess the quality of the soil and rock.

Mining: In mining operations, these rigs are used to explore for new ore bodies, determine the grade of the ore, and plan the mining process.

Construction: For construction projects, core drilling rigs can be used to test the strength of the foundation soil, install piles, and conduct other geotechnical investigations.

Advantages of Hydraulic Core Drilling Rig

The Full Hydraulic Core Drilling Rig offers several advantages over traditional drilling rigs:

High Efficiency: The hydraulic system allows for precise control of the drilling process, resulting in faster drilling speeds and higher productivity.

Flexibility: These rigs adjust drilling depths, angles, and diameters with ease, enabling diverse applications.

Low Noise and Vibration: The hydraulic operation reduces noise and vibration levels, which is beneficial for both the operators and the surrounding environment.

Better Core Recovery: The advanced design of the rig ensures better core recovery rates, providing more accurate geological information.

Hydraulic Core Drilling Rigs Use Guide

Here are some steps for using a Hydraulic Core Drilling Rig Machine:

- Site Preparation: Choose a suitable location for the rig, level the ground, and secure the rig in place

- Installation: Install the drill rod, drill bit, and other components according to the manufacturer’s instructions.

- Startup: Start the hydraulic system and check for any leaks or abnormal noises. Adjust the pressure and flow rate of the hydraulic fluid as required.

- Drilling: Lower the drill bit into the borehole and start the rotary table to begin drilling. Monitor the drilling process closely, including the drilling speed, torque, and core recovery.

- Core Retrieval: Once the desired depth is reached, stop the drilling and retrieve the core sample from the drill rod.

Full Hydraulic Core Drilling Machine Maintenance Tips

To ensure the long-term performance of your Full Hydraulic Core Drilling Rig, follow these maintenance tips:

Regular Inspection: Inspect the rig regularly for any signs of wear and tear, such as damaged hoses, loose bolts, or worn-out parts.

Hydraulic Fluid Maintenance: Check the level and quality of the hydraulic fluid regularly. Replace the fluid as recommended by the manufacturer.

Cleaning: Keep the rig clean to prevent the accumulation of dirt and debris, which can cause damage to the components.

Lubrication: Lubricate the moving parts of the rig, such as the drill rod joints and the rotary table, to reduce friction and wear.

Crawler Hydraulic Core Drilling Rig Troubleshooting

If you encounter problems with your Crawler Hydraulic Core Drilling Rig, here are some common issues and solutions:

Low Drilling Speed: Check the hydraulic pressure and flow rate. It could be due to a clogged filter or a malfunctioning pump. Replace the filter or repair the pump if necessary.

Poor Core Recovery: This may be caused by a dull drill bit or improper drilling parameters. Replace the drill bit and adjust the drilling speed and pressure.

Hydraulic Leaks: Inspect the hoses and connections for leaks. Tighten the connections or replace the damaged hoses.

Why choose YG Machinery

YG Machinery offers high-quality drilling rigs with advanced technology and excellent after-sales service. With YG Machinery, you can get a rig that is not only efficient but also durable and easy to maintain. So, if you are in the market for a full hydraulic core drilling rig, consider YG Machinery for a great investment.

WhatsApp/WeChat at +86 138 3715 9132