Sand blasting machine is an industrial tool designed to clean, smooth, or prepare surfaces by propelling abrasive materials at high velocity. Widely used across industries, these machines remove rust, paint, contaminants, or add textures to metals, wood, glass, and concrete. WhatsApp/WeChat/Phone: 86 138 3715 9132

Key Parameters of Sand Blasting Machine Price

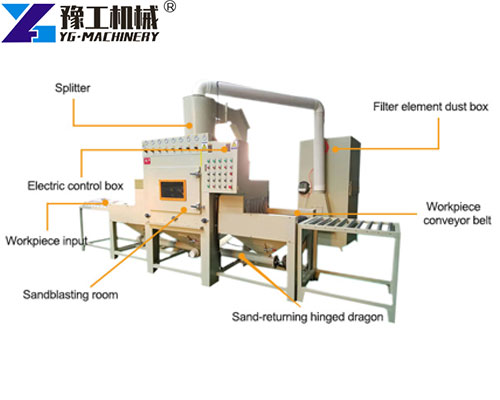

| Item | YG-800 |

| Machine Size | 3600*1800*2600mm |

| Dust Box Size | 1300*1300*2500mm |

| Work Max Size | 1200mm width, length is free |

| Speed | 0.5-2m/min |

| Machine Effect | according to craft and material |

| Spray Gun Quantity | 8-16 pieces |

| Power Supply | 380V/50HZ,3 phase five wires |

| Dust Removal Motor | 7.5KW |

| Separation Air Volume | 10m3/min |

| Compression Air Source | 2-7bar(kg/cm3) |

| Air Source Flow | 8-16m3/min |

| Noise | below 85db |

| Dust Emission | below 0.4mg |

| Working Environment Temperature | -10-40degree |

| Total Power | 9.8KW |

Types of Sand Blast Machines

Commercial Sand Blasting Machine: Built for heavy-duty tasks in industries like shipbuilding or construction, these high-capacity units handle large surfaces and tough materials.

Automatic Sand Blasting Machine: Equipped with programmable logic controllers (PLCs), these systems streamline repetitive tasks in automotive or aerospace manufacturing.

Small Sand Blasting Machine: Compact and portable, ideal for workshops, DIY projects, or delicate surfaces like jewelry.

Water Sand Blasting Machine: Uses water to suppress dust, perfect for environmentally sensitive areas or fire-risk zones.

Sand Blast Room: A fully enclosed workspace with ventilation and recycling systems, used for large components like aircraft parts or industrial machinery.

Application of Commercial Blasting Machines

Automotive: Removing paint from car bodies or cleaning engine parts using a commercial sand blasting machine.

Construction: Preparing concrete surfaces or restoring historical buildings with a water sand blasting machine to avoid structural damage.

Manufacturing: Deburring metal components in a sand blast room for precision engineering.

Marine: Stripping rust from ship hulls using high-pressure sand blasting machines with compressors.

Art and Restoration: Detailing sculptures or antiques with a small sand blasting machine for controlled abrasion.

Advantages of Automatic Sand Blasting Machine

Superior Efficiency: Automated operation accelerates surface cleaning, rust removal, and finishing by 3–5x compared to manual methods, ideal for high-volume projects.

Consistent Precision: Programmable controls ensure uniform results across batches, critical for intricate designs and industrial-grade quality standards.

Enhanced Safety: Enclosed systems minimize operator exposure to hazardous debris, toxic dust, and excessive noise, complying with workplace safety regulations.

Eco-Friendly Performance: Advanced filtration reduces airborne pollutants, while reusable abrasives cut waste generation, supporting sustainable operations.

Cost Savings: Reduced labor dependency, minimal maintenance, and long-term durability lower operational expenses over time.

Versatility: Adaptable settings handle diverse materials (metal, wood, concrete) and surface textures, from heavy corrosion to delicate refinishing.

Scalability: Seamlessly integrates into production lines for continuous, large-scale applications without compromising output quality.

Key Features of Sand Blasting Equipment

Compact Design: Space-saving footprint ideal for workshops with limited area.

High-Pressure Efficiency: Delivers rapid cleaning and finishing for small to medium surfaces.

Adjustable Controls: Customizable pressure settings for delicate or heavy-duty tasks.

Portability: Lightweight build with wheels/mobility options for on-site flexibility.

Safety Compliance: Sealed chambers reduce dust exposure and noise pollution.

Low Abrasive Consumption: Optimized nozzle design minimizes material waste.

Multi-Material Compatibility: Effective on metal, wood, plastic, and glass surfaces.

Easy Maintenance: Simplified access points for quick part replacement and cleaning.

Sand Blasting Machine With Compressor Working Principle

A sand blasting machine with compressor operates by forcing compressed air through a hose, which mixes with abrasive media (e.g., silica, garnet, or steel grit) in a pressure chamber. The mixture is ejected at high speed via a nozzle, impacting the target surface to remove contaminants. In a water sand blasting machine, water is injected into the airflow, creating a slurry that reduces friction and dust. Automatic sand blasting machines use sensors and PLCs to regulate pressure, abrasive flow, and movement, ensuring uniformity.

Sand Blasting Machine Usage Precautions

Protective Gear: Operators must wear goggles, gloves, and respirators, especially in open setups or sand blast rooms.

Abrasive Selection: Choose media based on material hardness; avoid overly coarse abrasives for delicate surfaces.

Machine Maintenance: Regularly inspect hoses, nozzles, and compressors for wear. Clean water sand blasting machines to prevent clogging.

Ventilation: Ensure proper airflow in enclosed spaces like sand blast rooms to avoid toxic fume buildup.

Pressure Checks: Over-pressurizing a small sand blasting machine can damage both the equipment and the workpiece.

WhatsApp/WeChat/Phone: 86 138 3715 9132